In the May issue of Emidas magazine, we mentioned an overview of powder coating technology: principles, processes, applications, and analysis of the current situation of some Vietnamese enterprises that are operating powder coating. Following the previous section, in this article, we will introduce readers to the powder coating technology of Japanese enterprises in Vietnam.

To carry out this article, we have received opinions from 2 Japanese sheet metal processing enterprises in Vietnam. For these companies, painting is considered an important stage that helps them complete their production chain and provide customers with a complete, high-quality service process.

Modern equipment - Strict process

When it comes to Japanese enterprises, perhaps it is impossible not to mention the superiority in product quality. In Japanese enterprises, we can easily see the meticulous investment in equipment, from bubbling systems to drying ovens, painting lines, etc., along with strictly controlled processes to ensure accuracy and high efficiency in work.

For example, in the surface treatment process before painting using zinc phosphate plating technology, the chemicals used in degreasing tanks, shaping tanks, and phosphate are strictly controlled: type of chemicals, newly mixed chemicals, supplementary chemicals, and replacement time.

Surface treatment line at Nissin Electric Company

The technical parameters of time, dipping temperature, contamination level, dipping form, and testing methods are specifically instructed to control the entire washing and cleaning line. The product surface after cleaning through the tanks has a phosphate layer to help the product resist corrosion. This phosphate layer will be checked and analyzed to evaluate the adhesion level, thickness, and composition.

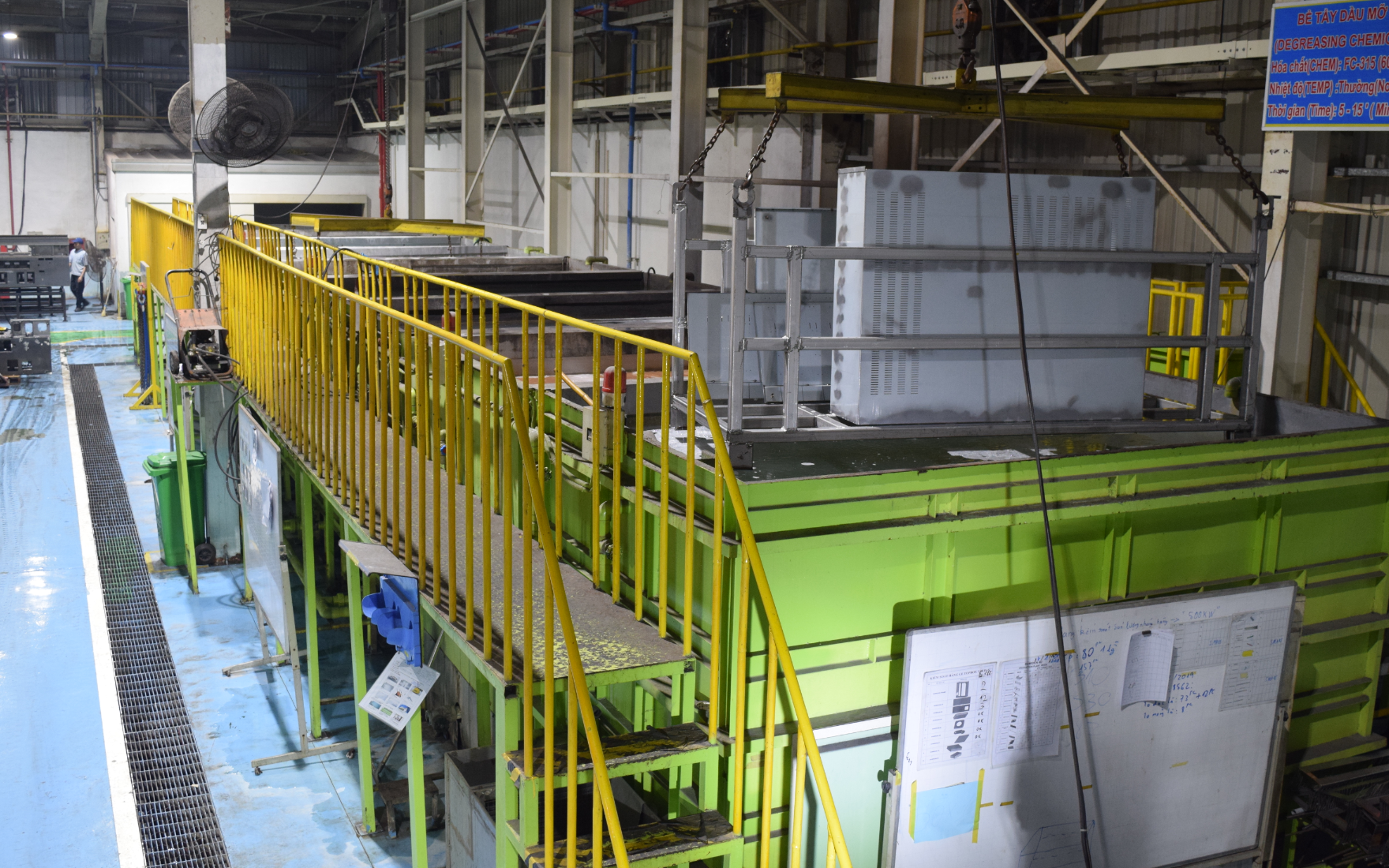

Surface treatment line at Kai Metal Asia Company

In particular, the two enterprises we interviewed for this article both have wastewater treatment equipment to treat part or all of the wastewater from washing tanks. Kai Metal Asia Company shares with us the following: "At our company, we have our own wastewater treatment equipment. Wastewater overflowing from the washing tanks or water storage tanks is treated by wastewater treatment equipment and then discharged outside the factory. Wastewater from the chemical storage tanks is collected by a professional industrial waste treatment unit. We conduct daily checks on wastewater treatment standards. In addition, the industrial park also conducts wastewater treatment inspections once a month to ensure compliance with standards."

In addition, Nissin Electric Company also has a wastewater treatment system from the washing tanks with a volume of about 70 m3, ensuring that the wastewater discharged into the environment does not cause pollution.

Such wastewater treatment systems are rarely installed by Vietnamese enterprises due to their high costs, but this shows the environmental and social responsibility of enterprises during production. Moreover, nowadays, environmental protection issues are becoming more and more concerning. Enterprises have to face pressure from governments, environmental management agencies, and customers about implementing environmental protection measures in their production processes. A self-equipped wastewater treatment system can be considered an investment in the sustainable future of enterprises while also helping them gain an advantage when penetrating the international market.

Product quality - the pride of Japanese enterprises

In the painting-drying stage, we can divide into 2 different processing methods for large-sized products and small-sized products.

Small-sized products are often painted-dried on a hanging system. When painting, the product is preliminarily cleaned, then moved into the paint booth. Here, companies use spray guns to paint the surface, which can be done by automatic spray guns or experienced workers directly holding the spray gun to operate. The more complex and nooks, crannies, and bulges in the product, the more complex and time-consuming the painting process.

Paint spray booth at Nissin Electric Company

After painting, the product moves through the conveyor system in a clean, sealed environment, the product will self-dry and go to the inspection area. This chain system at Japanese enterprises is strictly controlled from the manufacture of samples, how to mix paint, choose the type of paint, paint supplier, and what material to paint. For large-sized products that cannot use the hanging system, the enterprise will use a frying oven to dry the products, then design separate paint booths.

Drying oven at Kai Metal Asia Company

Large drying oven at Nissin Electric Company

Labor safety measures are implemented very strictly. The operators are equipped with glasses, gas masks, paint clothes and gloves. In addition, in an enterprise that also implements water-based electrostatic painting, the enterprise has designed additional water overflow tanks right at the painting location, whereby excess paint is sucked up and falls into the tank. Therefore, the painting space is always clean, contributing to environmental protection and protecting workers' health.

Workers painting at Kai Metal Asia Company

Product inspection is an important step that makes Japanese proud of their product quality. The product is thoroughly inspected through each stage, including the pre-processing stage, to ensure a perfect, good-quality paint layer. The product is surface inspected (appearance), size inspected by mechanical measuring tools, test gauges, and JIG; hardness inspection of materials; tolerance inspection of shape and position by 2D measuring machines and 3D CMM measuring machines. Especially check the deviation of paint color, gloss, and thickness of the paint layer with specialized equipment. This is the stage where Vietnamese enterprises and small businesses have not implemented or are implementing poorly, so the product is not yet competitive and exportable.

Inspection stage at Nissin Electric Company

Basically, we see that Japanese enterprises have more meticulous and synchronous investment in equipment than Vietnamese enterprises. Besides, with their long-term experience and sense of responsibility, Japanese enterprises always have continuous improvements to optimize production processes and ensure product quality.

In addition to equipment, human resource training is also very important. The enterprises have periodic training programs to improve the skills of their employees. Moreover, many management-level human resources are also trained or have practical work experience in Japan. These employees, after returning to Vietnam, became high-quality human resources and passed on their knowledge to other employees in the company.

Prospects and challenges

In Vietnam, along with the development of industries such as automobiles, industrial machinery, electricity-electronics, etc., the powder coating industry also has a lot of development potential. Nissin Electric Company shares as follows: "More and more foreign enterprises are interested in investing in or shifting production from China to Vietnam. In Japan, the aging of specialized engineers in fields such as welding and painting is a serious problem. I believe that Vietnam will develop further if young people can equip themselves with good skills and knowledge."

However, because Vietnam's supporting industry has not yet truly developed, the purchase of domestic paint materials or equipment still faces many difficulties. The dependence on imported raw materials is a difficult problem for many enterprises in many industries in Vietnam. For powder coating enterprises, the purchase of paint materials from abroad may be related to costs such as import taxes and international shipping fees, and sometimes there will be fluctuations in the price of raw materials on the international market, increasing production costs.

On the other hand, regarding human resources, in addition to issues related to professional knowledge and skill levels, Vietnamese human resources are also often commented on as lacking awareness of quality and safety. These issues pose a major challenge to the sustainable development of the powder coating field in particular and the industry in general in Vietnam.

※ We would like to send our sincere thanks to Kai Metal Asia Co.,Ltd and Nissin Electric Vietnam Co.,Ltd for contributing ideas to complete this article.